THIS IS THE REPORTS PAGE FOR THE GOLF COURSE # 1 WELL

6-14-2019

- I have talked to Ken Boester with KEBO Oil & Gas today regarding the staging to get the Golf Course Project in preparation to drill. The first step is to get a Drill Site Title Opinion. Ken will find a Title Attorney to start the process. We agreed to get everything together for the opinion by next week. I would like to have a Title Attorney selected and all the material in his possession by the end of next week. Our Landman (Mark Crawford) has reviewed the attached leases and is prepared to do the curative work necessary for the Title Attorney.

- I have been in talks with the land owners Attorney to procure an agreement for a pipeline to the gas tap and to work out an agreement for the use of the Salt Water Disposal (SWD) well on our lease.

I will send you an update the end of next week.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

6-26-2019

- I have started the title examination using Acaval Land Company. The first step is curative, to get a land ownership take off from sovereignty of the soil, to give a Land Attorney, to render his opinion.

- We have been in negotiations with the Land owners Attorney (Hoss Gwin) to get an agreement finished allowing us to use our existing pipeline connection on our Live Oak Creek Project for Golf Course Project. Note both projects have different land owners but are represented by the same attorney. The agreement will allow the Live Oak Creek owners to dispose of their salt water in the Salt Water Disposal (SWD) Well located on our lease. As always, you will get the best deal in negotiations before you make a well. We hope to have this wrapped up within the next 2 weeks.

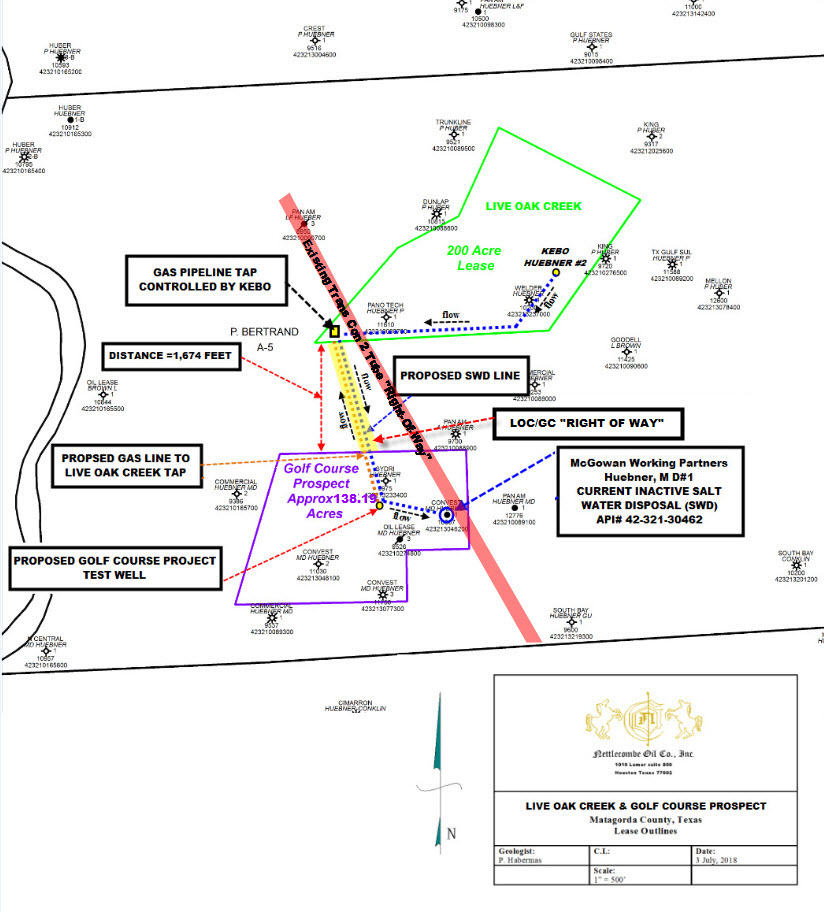

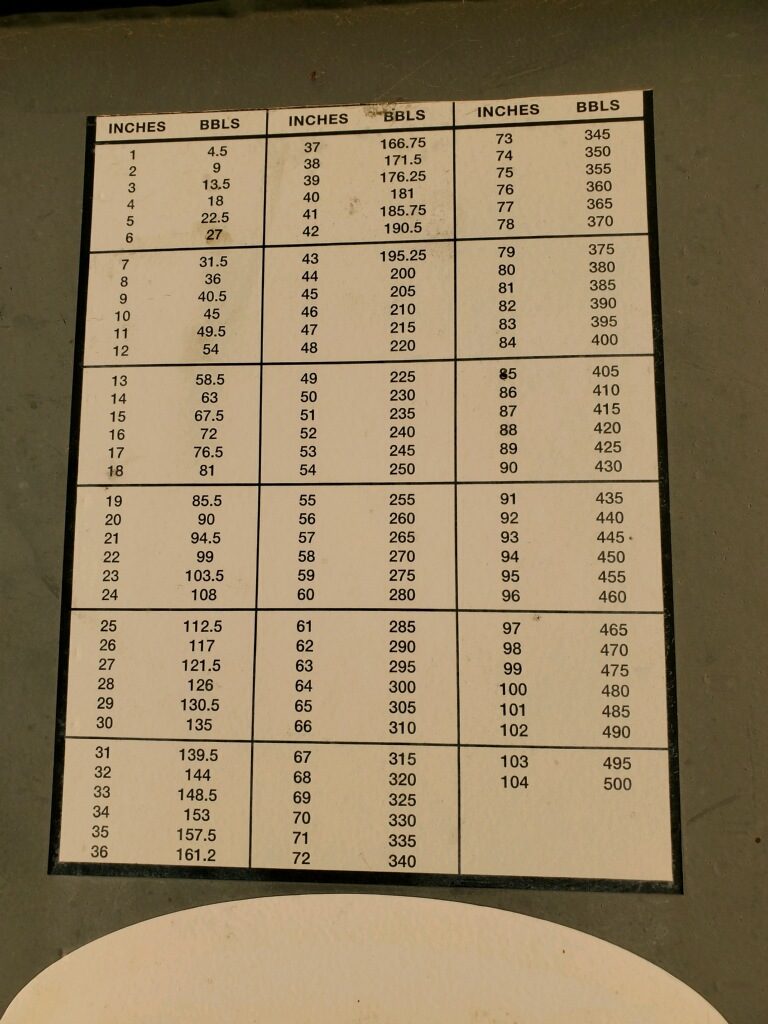

While in negotiations we went out to the Golf Course Lease and photographed the SWD Well, which I attached. I also attached the exhibit I made better explaining visually, what our needs are in the agreement for Hoss Gwin.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

7-3-2019

Happy 4th of July!

- I just finished the negotiations with the land owners Attorney (Hoss Gwin) today, on our agreement allowing us to use our existing pipeline connection on our Live Oak Creek Project for Golf Course Project. We got everything we needed before drilling the test well on the Golf Course Project. Hoss will have the agreement waiting on us when we return from 4th of July Holiday.

- Acaval Land Company should have all the curative done as mentioned last week before the end of the month, for the Title Attorney to render a title opinion.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

7-11-2019

Good News!

The Live Oak Creek, the sister to the Golf Course Project located 4200 feet north east of our test well on the Golf Course Project, was logged and evaluated over the 4th of July holiday. All the Information indicates a great well that came in better then planned, in that we picked up 4 additional sands. The Golf Course Project is located in the immediate up dip fault block to the Live Oak Creek, which allows itself to be even better then the well we just completed. I attached for your records my summary on the new well.

As mentioned last week, Hoss Gwin, the attorney for the Land owner on both the Live Oak Creek (New Discovery) and the Golf Course Project, promised he would have the pipeline/ SWD agreement done and sent to me by the time I return from the 4th holiday, I had it in my email on Monday. Note it is very important to have this agreement in force before we drill our well and after the Live Oak Creek well was drilled because to complete the new well they will need a SWD to dispose of water economically. With a SWD on the Golf Course project lease and the Natural Gas pipeline tap on the Live Oak Creek Project, we need each other. After our land people reviewed the agreement everything looks good except few minor points, which I have forwarded over to Hoss for his revision. With this agreement we stand to save over $100,000 on pipeline taping fees plus save on the time it would take to negotiate with the pipeline people, which can take 3 months to complete. So after we drill we will have a way to market.

Meanwhile Acaval Land Company is still assembling the curative for the Title Attorney.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

Signed Preliminary Post Analysis Summary Live Oak Creek

7-18-2019

KEBO OIL & GAS wrote:

Paul,

This confirms receipt of the exact X/Y’s calls. We will go ahead and survey and permit ASAP. I’ll go ahead and firm up a contract to drill with probably Lauson Drilling. Based on my conversations with them about their schedule we could be ready in about 60 days to spud. Exact timing depends on weather and unforeseen events in the contractors schedule. But that is my best estimate now regarding timing. kb

NETTLECOMBE OIL COMPANY, INC. responded:

Ken:

Thank you for the update on the Golf Course.

Per last weeks update, we have sent to Hoss Gwin the attorney for the Land owner on both the Live Oak Creek (New Discovery) and the Golf Course Project) our suggested corrections on the pipeline/ SWD agreement. He has been out of the office all week and should be back next Tuesday. My hope will be to finalize this agreement next week with him. I will update everyone next week as to my progress.

PAUL E.HABERMAS

7-26-2019

The surveyors have the necessary information to stake the well and have told me today that they will stake some time next week and will let me know the exact day when they get a better handle on their schedule. kb

8-1-2019

- The Landowners Attorney has returned from his trip. I talked to him regarding finalizing the SWD Agreement, he told me that his goal will be to have the finalized agreement to us next week.

- Good News! We have staked the Golf Course #1 location. See attached Surveyed well plat.

- KEBO plans to have the well permitted by late next week.

Survey Well Plat Kebo OG Golf Course Well #1

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

8-8-2019

Good News the Golf Course #1 has been permitted, see attached file. We have also finalized and recorded the final SWD agreement between us and the land owners, which is a very positive leap forward as I explained in earlier updates.

I believe we are +/- 45 days out from spudding the Golf Course #1 Project.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

8-15-2019

Ken will start building location as soon as possible, maybe next week.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

8-22-2019

Good News!

We got a field meeting set up for building surface with the land owner tomorrow. We will start building location next week. We have Lawson contracted to do a turnkey drilling of this well. Next week I should be able to get an accurate time as to when the rig will be moving in.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

8-26-2019

Met w/ Dudley Huebner, discussed location, he is not worried about Pecan trees, wants cut up for fire wood. He wants to try and save oak trees, if not will cut up for fire wood. Will let us land farm mud for agreed price with Ken of $10,000. Will let us use existing water well about 200 yards from location. Need to get him agreement authorizing us to spread mud.

8-28-2019

Met location contractor. MI dozer & compactor. Started pushing out trees, brush, leveling location & compacting.

8-29-2019

Moved in maintainer, continued leveling location & compacting. Shut down due to rain. Location area was already damp. Will keep checking on location, but will be at least 4-5 days with no rain before work can resume.

9-4-2019

Continued scraping off grass, leveling location & compacting.

9-5-2019

Hauled in 35 loads (900 tons) limestone, spread, leveled & compacted.

9-6-2019

Hauled in 24 loads (625 tons) limestone, spread, leveled & compacted.

9-7-2019

Leveled & compacted limestone, watering as needed. Dug out weak spots on main lease road & laid in 3 x 5 bull rock & leveled.

9-9-2019

Leveled & compacted limestone, watering as needed.

9-10-2019

Leveled & compacted limestone, watering as needed and watered location.

9-11-2019

Hauled in 5 loads limestone on main lease road, spread across soft spots in road.

9-12-2019

Early morning rains (1-1/2″). Drained water off entrance of location. Hauled in 5 loads wash rock, spread across low spots in location. Notified Lauson Drilling to shut down on setting seller & conductor. Fenced off location and reserve pit area. Dug reserve pit.

9-13-2019

More light rain late evening and early morning. Hauled in 3 loads of wash rock, spread across low spots in location. Continued digging reserve pit.

9-14-2019

Continued digging & completed reserve pit. Bladed final pass on location.

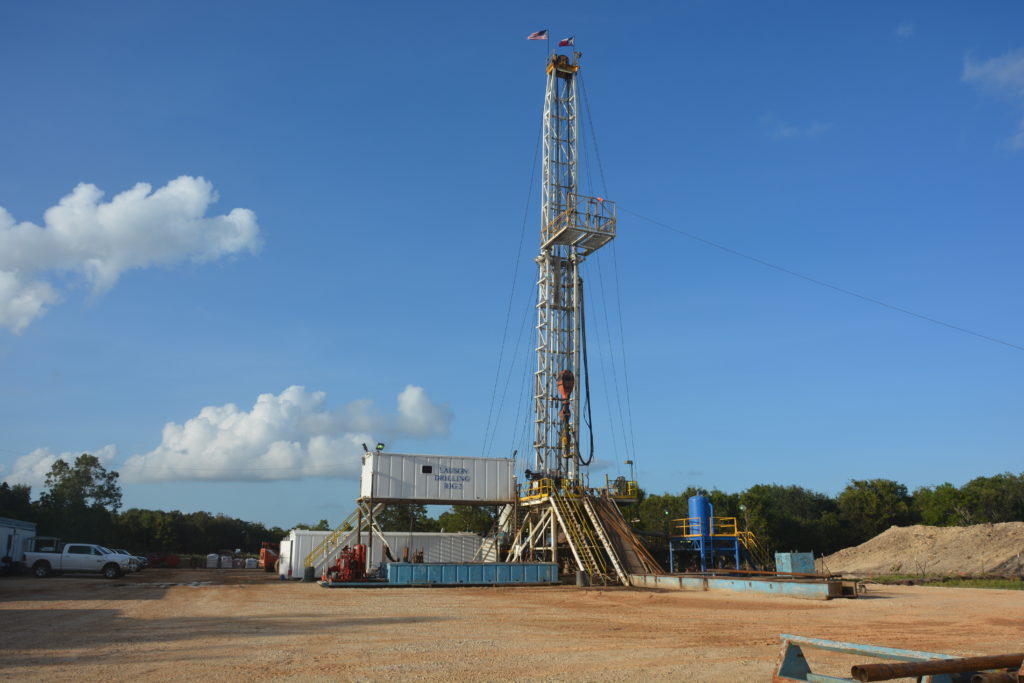

LAUSON DRILLING RIG# 2 ON LOCATION

9-17-2019

Finished RU. Spud well at 7:30 A.M. 9-17-19. Drilled 12-1/4” hole 0’ – 1,599’. Now C&CM. MW: 8.6#, Vis: 33sec, FL: NC. Survey: 1.2˚ @ 347’, 1.2˚ @ 597’, 0.9˚ @ 846’.

9-19-2019

Made wiper trip. C&CM. POOH. Ran, set and Advanced Cementing cemented 9-5/8”, 36#, J55, 8rd with 418 sacks “15:85:8” + ¼% AF-1 followed by 117 sacks “Standard” + ¼% AF-1. Had 45 Bbls cement returns. Top out with 50 sacks “Standard” + 2% CaCl. WOC. Cut casing. Weld on bradenhead. Now NU BOP. MW: 8.9#, Vis: 34sec, FL: NC. Survey: 1.2˚ @ 1,563’. Had to pump out reserve pit due to heavy rains.

09-20-2019

Finished NU BOP and tested to 250#/1500#. WIH with 8-3/4” bit. Drill out float joint and 10’ formation. Test casing seat to 12.0 ppg EMW. Drilled 8-3/4” hole 1,609-1,769’. Now drilling. MW: 8.9# Vis: 35 sec FL: NC.

09-21-2019

Drilled 8-3/4”hole 1769-3197’. Now drilling. MW: 9.1# Vis: 40 sec FL: NC. Survey: 1.6* @ 2066’, 0.2* @2564’.

09-22-2019

Drilled 8-3/4” hole 3179’ – 4452’. Made wiper trip @ 3352’. Now drilling. MW: 9.2# Vis: 40 sec FL: NC. Survey: 0.2* @ 3314’, 0.6* @ 4062’.

09-23-2019

Drilled 8-3/4” hole 4,452’ – 5,601’. Now making wiper trip. MW: 9.3# Vis: 45sec FL: NC. Survey: 0.2* @ 4812’, 0.2*@ 5563’.

09-24-2019

Finished making wiper trip. Drilled 8-3/4” hole 5,601 – 6,673’. Now working on mud pumps. MW: 9.6# Vis: 40 sec FL: 10 cc. Survey: 1.2 ˚ @ 6,311’.

09-25-2019

Finished working on mud pumps. Drilled 8-3/4” hole 6,673’ – 7,496’. Now making wiper trip. MW: 9.8#, Vis: 43sec, FL: 6.6cc. Survey: 0.4˚ @ 6,811’, 1.0˚ @ 7,496’.

FYI

We are currently drilling in the Anahuac Shale Between the Bottom of the Miocene and the top of the Frio. Our first objective is the Hamman 8400 Sand which I predict to seen in this well around 8143 MD. We won’t be down to this sand until early tomorrow morning.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

See mud log link below

09-26-2019

Finished making wiper trip. Drilled 8-3/4” hole 7,496’ – 8,207’. Now drilling. MW: 10.0#, Vis: 41sec, FL: 5.4cc. Survey: 1.3˚ @ 7,904’.

Here is the afternoon mud log and also attached my Geological Prognosis. Looking at the Mud Log it appears that we are running as predicted. It was my belief that we should run flat to low to the Sydri well and the Oil and Gas Huebner #3 in the top Frio down to the Upper Sloan. Once reaching the Upper Sloan we should see between 20 and 30 advantage in the Golf Course well. This structural advantage should continue down to the Tex – Miss. At the Tex-Miss the Structural advantage should grow to 60 feet. At the current rate of drilling we should reach the Upper Sloan by noon tomorrow. Note, the Huebner #3 is the closest well to the our Golf Course #1 well and produced 1.8 BCF + 15,000 BO out of the Main Sloan. As mention we should be high to this well by at least 20 feet.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

Golf Course #1_5IN_MD_Log_ 9-26

9-27-2019

All:

The last sample caught by the mud Logger was at 8740. The sample showed no sand but had 30% florescence (indication of oil). I believe that we are currently in the shale just above the Savage sand which I predicted to be at 8755. We should be hitting the upper Sloan at 8990. Note because of the good perm in the Sloan sands and the low pressure regionally in the Sloan (1200#) it is very common with 10.4 mud weight that the mud Logger will only get extremely filtrate flushed samples. In other words we won’t even see a Sloan sand. The next sand (Discorbis “A”) is normal pressure, which should be easily seen. This sand is predicted to come in high at 9180’. Also note the mud Logger takes a sample every 30 feet. The last sample taken at 8740, the following will be next samples taken:

8770

8800

8830

8860

8890 (Upper Sloan @ 8890)

8920

8950

8980

9010

9040

9070 (Main Sloan @ 9070)

9110

9140

9170 (Discorbis “A” @ 9180’)?

9200

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

Golf Course #1_5IN_MD_Log_9-27 afternoon report

All:

Afternoon Mud Logger report:

My suspicion this morning appears correct. It appears we hit the top of the Savage around 8740’, which is 15+\- feet higher then expected, good news. However it could be more sand development as well. The first minor Show is in the top of The Lewis Sand which I didn’t expect productive. We will have to wait for the Log.

Paul

09-28-2019

Drilled 8-3/4” hole 8770’- 9380’. Now drilling. MW: 10.6# Vis: 45 sec FL: 4.4cc. Survey: 0.6* @ 8906’.

They are making a bit trip now. Puts TD probably tomorrow evening. kb

09-29-2019

Drilled 8-3/4” hole 9380’ – 9600’. Now making bit trip. MW: 10.8# Vis: 45 sec FL: 4.2cc. Survey: 0.2* @ 9561’.

09-30-2019

Drilled 8-3/4” hole 9,600’ – 10,200’. Now C&CM. Preparing to make wiper trip and log. MW: 11.2#, Vis: 45sec, FL: 4.2cc.

NOTE: Estimated RU to log at 5:00 A.M. tomorrow morning (Tuesday 10-1-19).

Final Mud Log

Golf Course #1_5IN_MD_Final_Log_

All:

We reached TD at 6:20 this morning, currently we are preparing the well so it can be logged. My estimation is that we should be logging, barring any unforeseen hold ups sometime early morning which should give us a log to evaluate sometime before lunch. I will relay my initial opinions sometime in the afternoon and give a written post analysis within two days after we have received all the data.

Regarding the Tex Miss section in the mud log I was mostly encouraged by the apparent up dip nature to our well from the down dip wells. It appears that we are as much as 80 feet up dip from the Sydri well. We did get some streaming florescence in the Tex Miss which is encouraging for oil. Bottom line is we need to wait until the log is on the bank.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

All: Just got word from rig that Logging is going to be delayed. Lauson has decided to do a second wiper trip up to 8500′. Instead of RU to Log at 10:00 PM, we now estimated RU at 5:00 AM tomorrow morning. kb

10-01-2019

C&CM. Made wiper trip to casing seat. Wash & ream 10,154’ to TD. C&CM. Made second wiper trip to 8,500’. C&CM. Now POOH. Preparing to log. MW: 11.3#, Vis: 45sec, FL: 3.8cc.

10-02-2019

Finish POOH. RU Baker. Ran Induction Density Neutron Micro Log. Log on bank at 3:30 P.M. 10-1-19. Ran SWC. RD Baker. Now staging in hole with bit. MW: 11.4#, Vis: 45sec, FL: 3.2cc. Survey: 2.4˚ @ 10,185’.

10-03-2019

Finished staging in hole to bottom. Wash and ream 10,174’ – 10,200’. C&CM. Now making wiper trip to surface casing. WOO. MW: 11.3#, Vis: 44sec, FL: 3.2cc.

10-04-2019

Finished making wiper trip. C&CM. LD DP & DC. MW: 11.3#, Vis: 42sec, FL: 4.0cc. NOTE: Preparing to run 4-1/2” casing.

COMPLETION

10-05-2019

Ran 4-1/2″, 15.10#, P-110, 8rd casing to 10,126′ (FC @ 10,088′, DV toll @ 6,400′). C&CM. Waited on Halliburton 8 hours to deliver spacer. RU Halliburton. Now pumping 1st Stage cement. MW: 11.3#, Vis: 42sec, FL: 4.0cc.

10-06-2019

Halliburton cemented 1st Stage with 530 sacks Neo Chem + 0.3% Super CBL + 0.25% HR-5. Displaced plug with 52 Bbls ClayWeb treated water + 91 Bbls mud. Had full returns while cementing. Dropped bomb and opened DV tool with 800#. C&CM 3 hours. Cemented 2nd Stage with 2028 sacks Neo Chem with 0.1% HR-5. Displaced plug with 91 Bbls ClayWeb treated water. Had full returns while cementing. RD Halliburton. Set slips with 115,000# weight. ND BOP. Cut casing. NU tubinghead and capping flange. Cleaned mud tanks. Released rig at 7:00 P.M. 10-5-19. Will drop from report until completion resumes.

10-15-2019

Rig moved off location, had crew install fence across front of reserve pit to keep cattle out.

10-29-2019

Cleaned out rig ditches, and moved oak & pecan trees being cut up and stacked for landowner, trees removed before building location as agreed.

10-30-2019

Set 6″ centrifugal pump on reserve pit to circulate settled out mud on bottom of pit. Having trouble keeping pump primed because of heavy mud plugging suction. Started stripping up limestone on north side of location, using material to fill in rig ditching.

10-31-2019

Continued circulating settled out mud on bottom of pit & stirring with trackhoe. Pump lost prime, unable to reprime. Called for replacement pump, pulled pump off pit & returned.

11-1-2019

Set replacement pump, continued pumping off water & mud. Put discharge back in pit, circulated settled out mud on bottom of pit & stirring for 2 hours. Pull discharge out of pit and continued pumping out mud. Trackhoe started back filling pit, crowding mud to pump.

11-2-2019

Continued pumping out mud and trachoe continued back filling pit. Crowding mud to pump until mud too thick to pump. Started dipping out mud, crowding with dozer. Had backhoe continue digging out rig ditches, hauled in 15 yards dry limestone to back fill ditches.

11-5-2019

Continued back filling pit, dipping out mud, crowding with dozer.

11-6-2019

Continued back filling pit with dozer

11-7-2019

Continued back filling pit with dozer.

11-8-2019

Completed back filling pit. Back drug mud across pit area. Dressed off area around location.

NOTE: Will most likely have to dress area again and/or disc in mud at later date.

WO rig is scheduled to MI Monday and start attached procedure. kb

Golf Course #1 Initial Completion Procedure

11-12-2019

MIRU Ranger Workover Rig & equipment. Unloaded 251 joints of 2-3/8″ tubing w/ beveled couplings. Unloaded drill, bit & handling tools. ND 7-1/1″ 5k flange. NU BOP’s. PU & WIH w/ 3-5/8″ bit, 4 – 3-1/8″ DC & 30 joints of 2-3/8″ tubing. SWFN.

11-13-2019

Continued GIH w/ 3-5/8″ bit, 4 – 3-1/8″ DC & 2-3/8″ tubing. PU off ground, tagged up @ 6,362. RU power swivel, drilled & reamed down to 6,414′, tagged and drilled on DV @ 6,416′. WIH to 6,434′, circulated clean. SWFN.

11-14-2019

Continued GIH w/ 3-5/8″ bit, 4 – 3-1/8″ DC & 2-3/8″ tubing to 10,062′ tagged up (FC @ 10,088′). Circulated clean, small amount of mud on BU. POOH, LD DC & bit. PU 3-5/8″ bit & 4-1/2″ scraper. WIH w/ 2-3/8″ tubing to 10,062′. SWFN.

11-15-2019

Displace Clay-Sta fresh water out of well w/ 7% KCL. RD power swivel. POOH w/ tubing, bit & scraper. RU PLPS E-Line. WIH, ran GRN/Radial Bond Log from 10,044′ to 6,000′. Made 2nd log run w/ 1000# pressure. Good bond across zones of interest. POOH, RD PLPS. Changed out casing valve w/ bent stem, tested to 3000#. SWFN.

11-16-2019

RU Fitzco Tubing Testers. PU & WIH testing to 7000# w/ XN Nipple, 8′ pup joint, 4-1/2″ AS1-X 10K pkr and 198 joints of tubing, st down in DV tool @ 6,428′ (previous depth without elevation), pulled 15K over string weight to pull free. RD tubing testers, POOH w/ tubing, packer & BHA. Found J housing on packer bent in. PU & WIH w/ 3-3/4″ bit and 4-1/2″ scraper, tagged up on DV tool @ 6,428′. RU power swivel. SWFW.

11-19-2019

Tagged DV tool @ 6,428′, drilled thru in approximately 5 minutes. Reamed thru area numerous times, circulated clean, hung back swivel in derrick. Continued in hole to 10,062′ w/ 3-3/4″ bit and 4-1/2″ scraper. POOH w/ bit & scraper. RU Fitzco Tubing Testers. WIH w/ XN Nipple, 8′ pup joint, 4-1/2″ AS1-X 10K Pkr and 198 joints tubing testing to 7000#. Sat down again in DV tool @ 6,428′. RD testers, POOH. LD packer & BHA. No scaring on packer. SWFW.

11-20-2019

PU & WIH w/ 3-3/4″ bit & 3-3/4″ string mill. Sat down in DV tool @ 6,428′. RU power swivel, reamed thru area numerous times, until tight spot smooth. Circulated clean, hung back swivel in derrick, continued in hole to 10,062′ w/ 3-3/4″ bit and string mill to 10,062′, circulated clean. Recovered some small pieces of rubber, cement and metal. PUH, hung up @ 8,287′, 10K to pull free. Sat down at same spot. RU swivel, reamed until no drag or set down. Continued POOH, had drag @ 4,466′. RU swivel, reamed until smooth. Continued POOH, LD Bit & string mill. SWFW.

11-21-2019

PU & WIH w/ 3-3/4″ bit & 4-1/2″ casing scraper, ran slow watching for possible tight spots, WIH to10,062′. Recovered more rubber while circulating, circulated 2 BU. POOH, no drag seen, LD bit & scraper. PU & WIH w/ guide, XN nipple, 8′ pup joint, 4-1/2″ AS1-X 10K packer & 231 joints (7,283′) 2-3/8″ tubing testing to 7000#. SWFW.

All:

The Golf Course #1 was perfed at 2:00 today, immediately after perfing the fluid column rose 900 feet with a slight blow. The work over rig started to swab the well in but the swabbing unit broke, so a new swabbing unit will be out tomorrow morning to bring the well in. The well was left open to the frac tank on a 12/64th choke.

We should know more tomorrow.

PAUL E.HABERMAS

NETTLECOMBE OIL COMPANY, INC.

11-22-2019

Continued GIH w/ guide, XN nipple, 8′ pup joint, 4-1/2″ AS1-X 10K packer & total of 303 joints 2-3/8″ tubing testing to 7000#, set packer @ 9721.71′ (TOP) w/10k weight in packer, EOT @ 9737.33′, tested to 1000#. ND BOP’s, NU tree (5K), tested 7K. RD Testers, RU swab, swabbed well down to 1800′ (7 bbls). RU PLPS, WIH to perforate, ran correlation log, EOT @ 9737-‘, perforated 9863-70′ EL(9862-69′ NL) 6 spf 60 deg. 1-11/16″ HMX, no pressure after perforating, slight blow. POOH RD PLPS. RU swab, tagged fluid @ 1000′, made 4 swab runs, recovered 16 bbls, total fluid swabbed 23 bbls. On last swab run, unable to stop because of breaks in rig, hit pack off in lubricator, jerked threads out of lubricator. Put well on 12/64 choke to rig tank overnight.

11-23-2019

Choke plugged, SITP: 150#, made 2-1/2 Bbls before choke plugged. Skim of oil on rig tank. Opened choke, pressure bled to 0#. SWI. RU swab unit. SITP in 20 minutes 300#. Bled off to swab tank. Tagged fluid @ surface, pulled from 1,200′, recovered 4 Bbls water w/ trace of oil. Continued swabbing, made 28 swab runs, fluid level slowly dropped to last run @ 4,100′. Recovered 77-1/2 Bbls w/ trace of oil and small amount of solution gas. With no stop swabbing, fluid rate 9-10 Bbls of water, SWIFBU overnight. Total fluid recovered after perforating 100.5 Bbls, 61 from formation.

11-24-2019

SITP: 640#. Opened to swab tank bled to 0#. Tagged fluid @ 100′, pulled from 1,100′, recovered 3 Bbls water w/ trace of oil. Continued swabbing, made 15 swab runs, fluid level slowly dropped to last run @ 4,600′, recovered 43 w/ trace of oil and small amount of solution gas. SWIFBU. Total fluid recovered after perforating 143.5 Bbls, 104 from formation. SITP: 580#.

11-25-2019

SITP: 610#.

The Tex Miss 2 sand has tested formation saltwater. Our plans are to set a through tubing bridge plug over current perfs and recomplete to the Tex Miss 1 through perfs yet undetermined. The proposed perfs on log cut are preliminary. The well will be shut in until SITP stabilizes before wireline work for TTBP is commenced. The TTBP procedure takes several days to be assured it works correctly.

11-26-2019

SITP: 620#.

The attached procedure will probably commence next week, provided that the SITP stabilizes over the next few days. kb

Golf Course #1 Proposed Subsequent Completion Procedure 11-26-19

11-27-2019

SITP: 630#.

11-28-2019

SITP: 630#.

11-30-2019

SITP: 630#.

12-1-2019

SITP: 630#.

12-6-2019

All:

I talked to Ken this morning, he has the Wireline crew on the Golf Course 1 well this morning to set a Through the Tubbing Bridge Plug on the Tex-Miss 2. This takes a couple days, but they will be working on the weekend. I expect to be perfing the Tex-Miss (Zone 1) next week.

Paul

12-7-2019

SITP: 630#. MIRU PLPS, & Ermis Pump Truck. Pressured up on lubricator to 675# before opening well on every run opened. WIH w/ 1.73″ GR thru perforations at 9,863’ – 9,870′, POOH. PU & WIH w/ TTBP, ran correlation log, set umbrella at 9,850′, POOH. WIH w/ Bridging Material, tagged @ 9,824′, TTBP appears to not to have deployed out of carrier properly. Dumped Bridging material. (After dumping cement, possibly only have 6′ of rathole below perforations @ 9,798′ bottom shot), POOH. WIH, w/ bailer, dumped 5′ cement on TTBP, POOH. SWFN.

12-8-2019

SITP: 630#, made 3 bailer runs dumping 5′ cement per run. Pressuring up each run to 675# w/ Ermis Pump Truck. PBTD should be 9,806′. SWFN, RD pump truck.

12-10-2019

SITP: 590#. MIRU Texas Swab Unit. Bled pressure to swab tank. Tagged fluid @ surface, made 7 swab runs, deepest pull from 3,800′. Fluid feeding in, recovered 30-1/2 Bbls, capacity to 3,800′ 15-3/4 Bbls. SWI. SW, RD PLPS & swab unit.

12-13-2019

MIRU Ranger Workover Rig & equipment. Bled 575# off well to rig tank. ND tree, NU Bop’s. Released 4-1/2″ AS1-X @ 9,721. Attempt to reverse out, pressured up to 1500#, unable to circulate. Started POOH, SWFN.

12-14-2019

SITP: 150#, bled off pressure. POOH w/ tubing packer & BHA, rubber missing off packer. PU 3-5/8″ bit, WIH. Tagged cement on TTBP @ 9,795′. RU power swivel, started drilling on cement, drilled to 9,797′ (reversing) started plugging off. Started circulating long way, drilled to 9,799′. Started plugging off, circulated clean. SWIFW.

12-17-2019

SITP: 150#, bled off pressure. Tagged TTBP/Cement @ 9,799′, drilled up, TTBP and pushed to 9,980′. Circulated clean, POOH w/ tubing & bit. RU PLPS. WIH w/ 3.625″ GRJB, to 6,422′, ran correlation strip, POOH. PU & WIH w/ CIBP, ran correlation, CIBP did not set. POOH, SWFN.

12-18-2019

SITP. 150#, bled off pressure, WIH w/ CIBP, ran correlation, CIBP did not set. POOH, another o-ring failure. Replaced, WIH ran correlation, and set CIBP 9850′, POOH tested packer & casing to 1000#. Dump bailed 20′ cement on CIBP, PBTD 9830′. POH, RD PLPS. RO Fitzco tubing testers, PU & WIH w/ guide, XN nipple, 8′ pup, 4-1/2″ AS1-X packer, 234 joints, 2-3/8″ 4.70# L-80 tubing w/ beveled collar & 69 joint same tubing w/ regular collars. Set packer @ 9703.41‘ w/ 12k on packer, EOT @ 9719.68′. SWFN.

12-19-2019

Well dead, RU swab, swabbed out 7-1/2 Bbls of 7% KCL loaded water. RU PLPS. WIH, ran correlation log. Perforated 9,794’ – 9,798′ EL (9,793’ – 9,797’ NL) 1-11/16″ 6 spf 60 degree. No pressure increase, POOH, RD PLPS. RU swab, tagged fluid @ 1,200′ (800′ increase) made 6 swab runs, deepest pull 2,950′ had tail gas on last run, recovered 25-1/2 Bbls. Well stared flowing. Put well on 14/64” adj. choke, FTP: 310#, on BU (38.5 BBLS). Pressure dropped to 200#, gassing, flowing in heads 3 BPM, opened choke 24/64”, well flowed 7 Bbls in 2 hours w/ 35% oil cut, shut well in. Checked choke, choke clear. SITP: 500#, opened well on 30/64” choke, pressure started dropping, dropped to 65#, estimated gas, 150-200 MCFD, 3 BPH, oil cut from 35-85%. Put well back on 24/64” choke. Set frac tank, had crew tie frac tank into well. Shut in TP: 540#, opened on 24/64” choke, monitored well. FTP from 300-400#, left well flowing overnight.

12-20-2019

FTP: from 290#-375# on 24/64” adjustable choke, 16 hours production 34 BO, 18 BW. 150 MCFD. Gas estimated unable to estimate gas accurately going into frac tank. RD workover rig, released all equipment. Left well on production to frac tank.

12-23-2019

12-24-2019

FTP from 260# on 24/64 adjustable choke, 5 BO, 55 BW. 50-100 mcfd. Gas estimated flowing into frac tank. Set 4’x20′(refurbished) heater treater, tied in dumps, lines and controls. Dug ditch from well to heater, tied into heater treater, back filled ditch. Filled heater w/ 30 bbls oil and water from frac tank.

Golf Course #1 Production 12-24

12-25-2019

FTP: 250# on 24/64″ choke. 274 MCFD (spot rate 280 MCFD) (flaring) + 15 BOPD + 45 BWPD. Note that we are measuring gas through a meter we installed off a heater treater we installed a couple days ago. The gas is not hooked to sales yet. We have scheduled adding perfs in the Upper Lobe of the TM 1 tomorrow at depths 9780-90′ (EL). kb

12-26-2019

FTP: 250# on 24/64″ choke. 275 MCFD (Flaring) +20 BOPD + 30 BWPD. Preparing to add perfs 9780-90′ (EL). kb

12-27-2019

Added perfs 9780-86′ (EL). A.t 7:00 AM today FTP: 600# on 16/64″ choke. 413 MCFD (flared) + 12.5 BO + 35 BW (18 hours). kb

12-30-2019

Production Golf Course #1 12-30-19

01-01-2020

FTP from 500# on 16/64” adjustable choke, 25 BO, 25 BW, 383 MCFD.

Hauled in 22 tons of pea gravel, had backhoe & crew spread and level for production tanks to set on. Set & leveled tanks hung landing. SDFD.

01-02-2020

FTP: 450# on 16/64″ choke. 357 MCFD + 30 BOPD + 30 BWPD. Hauled 140 bbls water from frac tank.

01-03-2020

FTP from 440# on 16/64” adjustable choke, 25 BO, 35 BW, 344 MCFD.

Started tying in load lines, dump lines on tanks, had backhoe fill in bad spots in main lease road, started building SDFD.

01-04-2020

FTP from 425# on 16/64” adjustable choke, 10 BO, 60 BW, 331 MCFD.

Continued and completed tying in dump, circulating lines & bypass around heater tank. Installed bull panel fence around facility. Completed firewall, used excess material to repair bad spots in road.

01-13-2020

Production Golf Course #1 01-13-20

01-14-2020

FTP: 145#, 18/64, 8.4 BO, 44.8 BW, 213 MCFD. MIRU Ranger Workover Rig & Equipment. SWI, loaded well w/ 28 Bbls 7% KCL pressure increased to 2800-3000# 1/2 BPM, displaced tubing with 38 Bbls, pressure dropped to 700#, bled to 0#. ND tree, NU BOP’s. Released packer, POOH w/ tubing, packer, pup & XN. SWFN.

01-15-2020

No pressure on well. RU PLPS. WIH w/ 3.62″ GRJB, ran correlation, bottom @ 9,812′, POOH. WIH w/ CIBP, ran correlation log, set CIBP @ 9,850′, POOH. Tested CIBP to 1000#. Bump bailed 20′ cement on plug, PBTD 9,830′, POOH. RD PLPS. PU & WIH w/ XN nipple, 8′ pup joint, 4-1/2″ AS1-X packer, 285 joints (234 w/ beveled collar on bottom), set packer @ 9,171.02′ w/11 on packer, EOT @ 9,188.02′, tested to 500#. ND BOP’s, NU tree. SWFN.

01-16-2020

No pressure on well. RU swab, swabbed to 3,300′ (12-34 Bbls). RU PLPS. WIH, ran correlation log, perforated 9,297’ – 9,300′ EL 1-11/16″ 6 spf 60 deg, no pressure after perforating, POOH. RD PLPS. RU swab, tagged fluid @ 1,400′. Made 5 runs, fluid came up to 800′ w/ 25 Bbls recovered, oil cut @ 15-20%. On 11th run BU 37 had 5% oil cut. 12th run fluid @ 750′, pulled from 1,450′. Had 20% formation sand w/ 5% oil cut. Made 2 additional runs. Sand appeared to be clearing up, w/ 54 Bbls recovered 5-10% oil cut. Well started flowing in heads @ 5-10#. Made 14 Bbls total fluid in 1 hour. Put on 18/64” choke to production water tank overnight.

01-17-2020

No pressure on well, 18/64” choke. Made 2.8 BO, 5.6 BW overnight. WIH w swab, tagged 900′, made 13 swab runs, deepest pull from 2800′. Recovered 41 Bbls 5-10% oil cut, well started flowing in heads @ 5-10#. Made 19 Bbls total fluid in 1st hour. Flowed on open choke for 3 hours, recovered 58 Bbls. Total fluid recovered 119 Bbls. Put on 36/64” choke to production oil tank overnight.

01-18-2020

No pressure on well, 18/64” choke. Made 5 BO, 3 BW overnight. WIH w swab, tagged fluid @ 1700′, made 10 swab runs, deepest pull from 2800′, recovered 28 Bbls 5-15% oil cut, well started flowing in heads @ 20-60#, put well to production tank on open choke. Made 11-1/2 Bbls total fluid in 1st hour, 2nd hour, FTP 15-40#, flowed 5 Bbls, 3rd hour, FTP 0-15#, made 4 Bbls & loaded up, recovered 20-1/2 Bbls flowing. RU swab, fluid scattered, pull from 2000′, recovered 2 Bbls, 2nd run tagged @ 2700′ scattered, pulled from 4700′, recovered 6 Bbls, 3rd run tagged @ 1800’, pulled from 3800′, recovered 4 Bbls, 4th run, tagged @ 1200’, pulled 3600′, recovered 3 Bbls. 5th run, sat down @ 2800′, recovered 3 Bbls. Recovered total 18-1/2 Bbls. Put on 48/64” choke to production oil tank overnight, monitored by gauging company. Recovered total of 67 total Bbls swabbing & flowing w/ 5-15% oil cut. Well had no flow overnight.

01-21-2020

No pressure on well. Loaded & displaced tubing with 36 Bbls 7% KCL @ 2000#, 1-1/2 BPM. ND tree, NU BOP’s. Released packer, POOH, w/ tubing, packer pup & XN nipple. RU PLPS. WIH w/ GRJB (3.625″) to 9310′, ran correlation log, POOH. WIH w/ CIBP, ran correlation log, set CIBP @ 9280′, POOH. Tested to 1000#. Ran & dump bailed 20′ cement on CIBP. PBTD 9260′. SWFN.

01-22-2020

No pressure on well. PU & WIH w/ guide, XN nipple, 8′ pup joint, 4-1/2″ AS1-X 10k packer 278 joints of 2-3/8″, 4.70#, N-80 tubing (234 joints w/ beveled collars). Set packer @ 8947.83′ w/ 8K weight on packer, EOT @ 8964.02′. Tested to 1000#. ND BOP’s, NU tree. RU swab, swabbed to 6700′, recovered 26 Bbls. SWFN.

01-23-2020

No pressure on well. WIH w/ swab, pulled from 8000′, recovered 2 Bbls, total recovered 28 Bbls. Fluid @ 7200-7300′. RD swab, RU PLPS. WIH, ran correlation strip, corrected EOT @ 8980′- (ELM). Perforated 9106-10′ ELM (9108-12′ NL) 6 spf 60 deg. 1-11/16″, no instant pressure. Pressure increased to 850# while POOH. RD PLPS, SITP: 850#. Opened on 12/64” adjustable choke thru heater treater, flaring @ 460 MCFD. Pressure came down to 750#, rate dropped to 141 MCFD. Rocked choke, and increased to 13/64”, well unloaded an ungaugable amount of load water after 0 hours. FTP stable @ 800#, flaring 500 MCFD. RD Ranger Workover Rig & equipment. Flowed well thru production equipment for 20 hours. FTP at end of test 680#, 12.5/64” adj. choke, 495 MCFD, only unloaded 2 Bbls, lad water. Shut well in. Should only have about 2 Bbls loaded water left to recover.

02-10-2020

We have been waiting on a contract for a new sales point from Kinder Morgan to tie this well into gas sales. Today, KM said they have been “backed up” but working on it. Our gas marketer says the last KM contract took three weeks to get it out of them, so we should have something soon. kb

02-26-2020

Brought in backhoe, dug out trees, and leveled ROW from location to the west toward Kinder Morgan pipeline along railroad. Lease crew strung 2-3/8″ line from heater treater to approximately 300′ from pipeline (anticipated tap point). Screw line together.

02-27-2020

Started digging ditch from production facility toward KM sales line. Crew coated line and put in ditch, back filled open ditch.

NOTE: Spoke w/ Harrison Harp, Kinder Morgan project manager, their anticipated start date for tap is 3-9-20.

02-28-2020

Continued digging ditch for gas line to sales point. Put line in ditch and rough backfilled ditch to keep out cattle.

02-29-2020

Continue back filling ditch and dressing off. All ditch covered, but not dressed off.

03-05-2020

Crew began breaking out lines from heater treater. Prepared to move and set HP LP separators for gas sales.

Current SITP is 1020#. Kinder Morgan is scheduled to start tap and gas sales meter construction on Monday the 9th. If they indeed get started then, I would estimate they we could turn on to sales about 3 or 4 days later, March 12th or 13th. kb

03-07-2020

Set HP & LP separators. Started tying in dump & gas lines. Backhoe continued leveling and dressing off line to sales point. Dug out broken down cattle guard and back filled with limestone.

03-08-2020

Continued and completed tying in HP & LP separators. Backhoe started stripping up limestone on north side of location to use for sales point. KM is supposed to start tap 3/3/20.

03-11-2020

No activity. Waiting on KM tap.

03-12-2020

No activity. Waiting on KM tap.

03-13-2020

No activity. Kinder Morgan is going to survey the tap & meter site Monday and we will commence operations Tuesday.

03-14-2020 No activity

03-15-2020 No activity

03-16-2020 No activity

03-17-2020 No activity. Kinder Morgan is shutting down office operations due to Corona virus, so expect further delays on pipeline tap.

03-18-2020 Kinder Morgan on location for tap. Dug out and exposed line. Surveyors also on location.

03-19-2020 Kinder Morgan on location making tap and building riser.

03-20-2020 Kinder Morgan on location tying in riser and back filling tap point.

03-21-2020 Kinder Morgan almost complete with hookup, need to install instruments and should be finished on Monday.

03-24-2020 Had crews & BH load out reboiler, contact tower, misc. piping, connections and move to sales point from well site. Built pad for dehy, set reboiler and contact tower. Started tying in to sales lines. Finished digging ditch to sales point, ran line and stubbed up on dehy pad. Tied into KM sales point. Backfilled ditches & had backhoe fill in holes in road to sales point.

03-25-2020 Kinder Morgan technicians working on meter run and communications tower. Crews completed tying in on dehy. SITP 1030#. Opened well on 6/64 choke, purged thru production system to flare valve at sales point. Pressured line and dehy to 750#. Put dehy in service and crew built fence around dehy. BH repaired holes in road to sales point. Flared gas for approximately 5 hours until KM ready. Put well to sales at approximately 3:15 PM. FTP 1000# 6/64, 180 MCFD, dew point 4#, KM line pressure 815#. Left well on production.

03-26-2020 FTP 860# 6/64”, 140 MCFD. Dehy malfunctioned and overheated. Attempted to make repairs, unit too hot to make repairs. SWI. Will make repairs in AM.

03-27-2020 Vacuum truck emptied burnt glycol out of reboiler. Crew and BH pulled fire tube on dehy reboiler, cleaned burnt build up out and replaced fire tube. Replaced bad controls. Filled w/ glycol. SITP on well 900#, opened on 6/64” adj. choke, gas rate 170 MCFD. Lit dehy, set hi temp shut down, monitored & let burner cycle numerous times. Left well on production.

03-31-2020 Well loaded up, FTP 830# (LP 815#), sales 418 MCFD, spot rate 75 MCFD. SWI. Had crew take down fence at production facility, backhoe pulled down firewall. Set 3 stage compressor, started tie in on discharge & dump lines. Left well shut in overnight.

04-01-2020 Continued and completed compressor tie in. SITP 950#. Opened well to production facility, started compressor. Monitored for approximately 5 hours, making adjustments to suction and RPM on compressor. Well fairly stable, FTP 780# on 9/64″ adjustable choke. Selling on spot rate 360 MCFD. Left well on production.

04-06-2020 See attached production Report

Golf Course #1 April Production

04-09-2020

04-14-2020

04-15-2020

Golf Course Production 4-15-20

4-22-2020

Production Golf Course #1 4-22-20

In reaction to the current, low crude oil pricing, Kebo has implemented the following policies:

1) We are not going to sell crude into the current price market,

2) We will try not to shut in any producing wells,

3) We will try to curtail production as best we can, but in most cases, especially on pumping wells, this is not feasible,

4) We are adding storage so we have the ability to stock pile for as long as possible. We estimate we will have storage for the next 30 to 60 days; maybe longer on low producers. We have been advised we may have some pricing relief in July, but nobody knows for sure. We will go on as long as we can with these plans, but at some point, we may have to shut in. We feel that in some cases if we shut in, we may not get the wells back to producing at a later date, plus leasehold could be jeopardized. We feel this is a temporary situation and we need your cooperation to timely pay your monthly JIB, even though there is no crude revenue at this time.

*I apologize in advance if you are receiving this multiple times, this is because you are on multiple wells.

Respectfully,

Ken Boester

CEO

04-27-2020

Production Golf Course #1 4-27-20

7-10-2020

July 2020 Golf Course #1 production